Australia's most sophisticated laser microfabrication facility, capable of machining materials with extraordinary precision down to the size of a human hair, has been unveiled at Macquarie University.

Funded by the Commonwealth's National Collaborative Research Infrastructure Strategy (NCRIS) scheme, along with support from Macquarie University and the NSW Government, the ANFF-OptoFab Multi-axis Laser Microfabrication Facility was officially launched on Tuesday 5 March by Distinguished Professor Michael Withford and the OptoFab team.

During the launch, speakers paid tribute to the late physicist and former Deputy Vice-Chancellor (Research) Professor Jim Piper, an early pioneer of micro-scale laser processing in Australia who established Macquarie's laser machining initiative in the early 1990s.

Guests at the official opening included Australia's Chief Scientist and Macquarie alumna Dr Cathy Foley, Deputy Vice-Chancellor Research, Professor Sakkie Pretorius, and Professor Piper’s family.

Nationally important

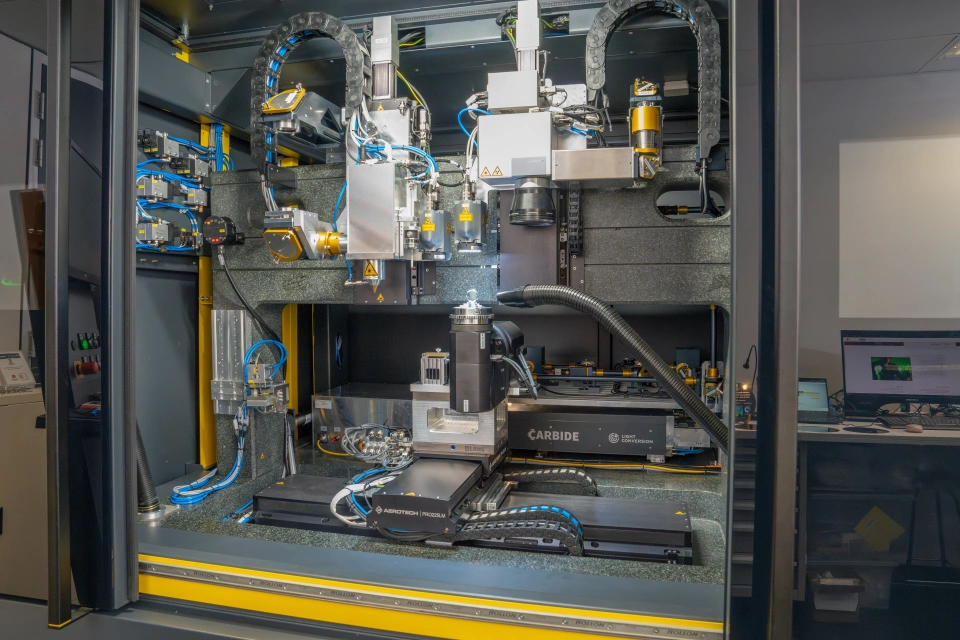

“I believe this cutting-edge facility, with its advanced hardware and software control, is now the most sophisticated laser microfabrication system in Australia, and indeed one of the most advanced worldwide,” said Professor Withford at the opening.

Dr Foley agreed, noting that the new facility firmly establishes Australia’s microfabrication capabilities, underpinning innovation across industries ranging from biotechnology and telecommunications to astronomy, microelectronics and industrial processing.

OptoFab at Macquarie University is one of eight nodes of the Australian National Fabrication Facility (ANFF), making pioneering fabrication equipment accessible to a wide range of users.

ANFF is a nationwide resource under the umbrella of Australia’s National Collaborative Research Infrastructure scheme.

The facilities service Australia’s “largely hidden” photonics industry, worth $4.3 billion to the Australian economy each year, according to Dr Foley.

"Australia’s approach to national research infrastructure means we have world-class, top-of-the-range research tools despite a modest research budget,” Dr Foley said.

Dr Foley, who was an undergraduate at Macquarie when Professor Piper was a physics lecturer credits the esteemed educator as an important influence in her life. She said Professor Piper created a safe and supportive culture for women in the school of physics.

“Back in the 70s, laser technology was a solution looking for a problem,” Dr Foley said. "Pushing the boundaries of science – which Jim did in truckloads – pushes us to imagine new ways to do things.”

Propelling research

Professor Pretorius said the advanced laser facility builds upon Professor Piper's pioneering work and is pivotal for maintaining Macquarie's research competitiveness.

“Jim Piper was a leader in the field of laser physics in Australia and internationally, and his generous mentoring of generations of graduate research students and postdocs changed the landscape in many disciplines, especially laser physics,” he said.

Professor Pretorius, who succeeded Professor Piper as Deputy Vice-Chancellor Research in 2013, recalled his first meeting with his predecessor at a conference more than a decade ago.

“I asked Jim, ‘How did Macquarie achieve such outstanding research outputs with modest external funding?’ He looked straight at me and replied, ‘Magic!’”

This deceptively simple response spoke volumes about Professor Piper’s strategic mindset and ability to maximise resources, Professor Pretorius said.

“Jim's 'magic' was really his genius at empowering people and finding creative ways to elevate Macquarie's research impact – so this new facility, which continues this innovative spirit, is a fitting tribute to his lasting vision.”

Laser machining

Macquarie University has specialised in laser microprocessing for over 20 years, with Professor Piper helping to establish commercial outcomes such as machining components for medical technology clients.

"Industry expectations compelled us to take a step change in capability, and with this new system we can laser-process extremely complex parts that simply weren't possible before," Professor Withford said.

Built by German laser machine manufacturer Pulsar Photonics to Macquarie University’s specifications, the facility is among a handful worldwide with such a high level of laser processing dexterity. It cements a remarkable legacy started by Professor Piper over 30 years ago in recognising the tremendous potential of laser precision at the microscale.

"It's an amazing piece of engineering," Professor Withford said.

Contact:

Phone:

Email: